Elastyczni

i niezawodni

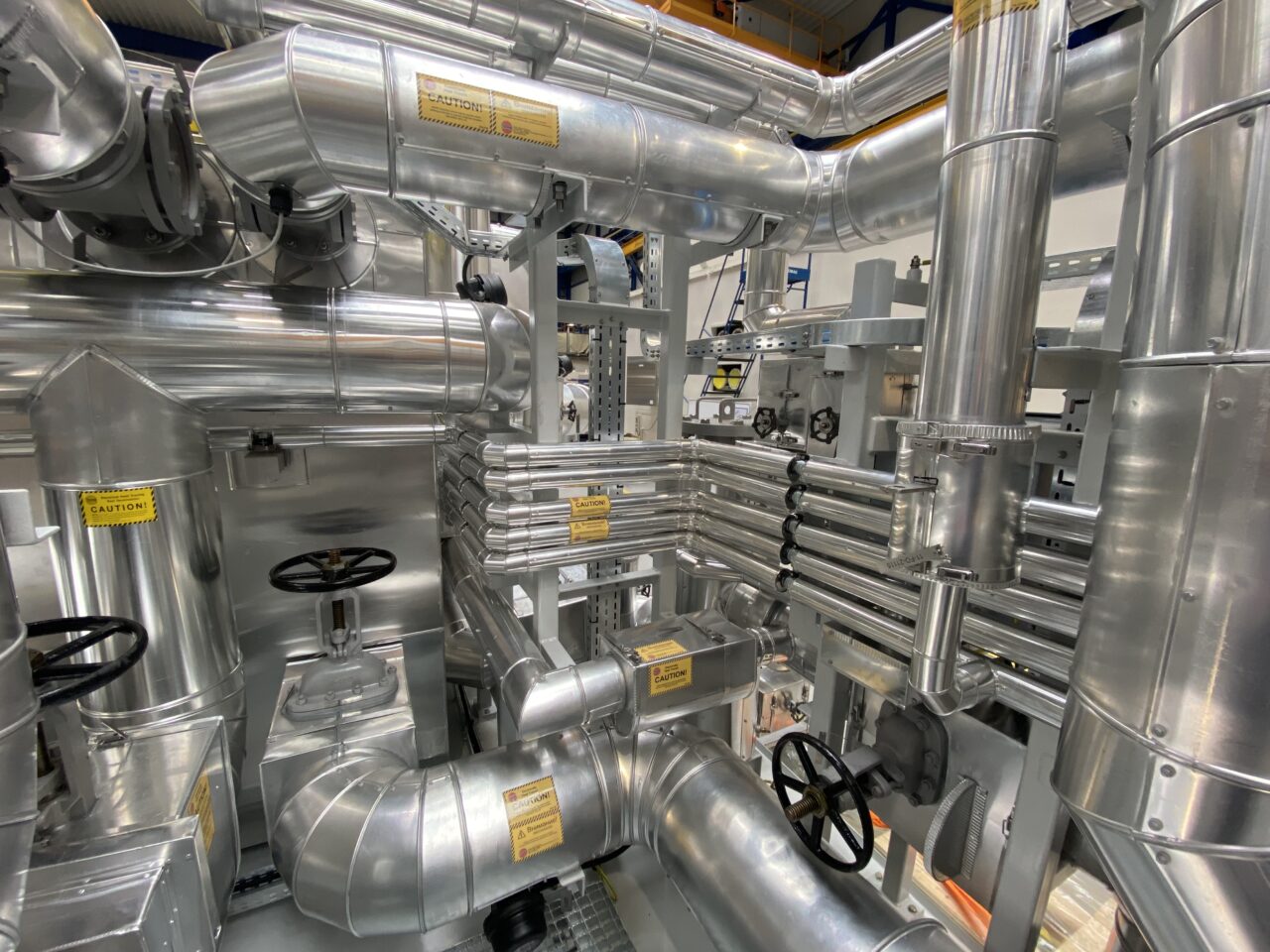

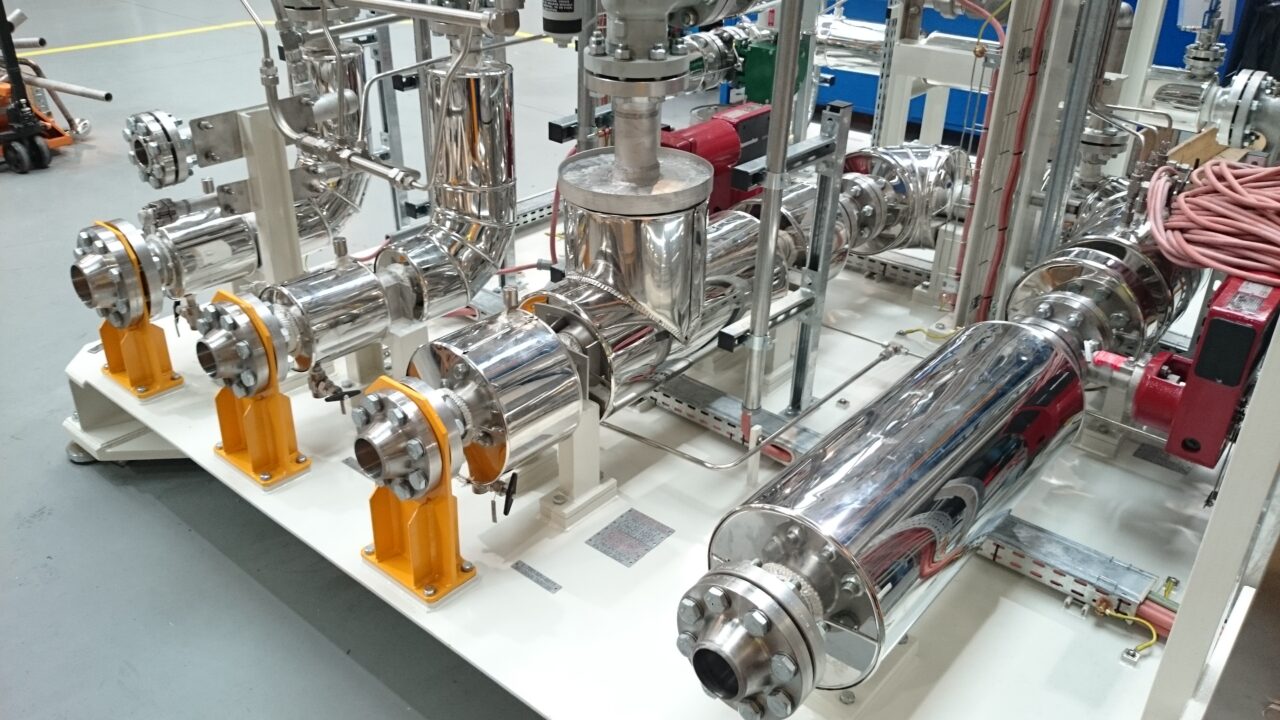

PetroStal to lider na rynku w branży izolacji przemysłowych. To co nas wyróżnia to przede wszystkim wysoko wykwalifikowana kadra, nowoczesna technologia oraz wszechstronność. Świadczymy kompleksowe usługi dla następujących branż:

Wykonamy dla Ciebie

Profesjonalni

i efektywni

Stawiamy przede wszystkim na jakość i profesjonalizm. Naszym klientom pomagamy osiągnąć nie tylko efektywność energetyczną, ale także sukces przemysłowego przedsięwzięcia!

Dlaczego PetroStal ?

Doświadczenie

Jesteśmy zgranym zespołem specjalistów z wieloletnim doświadczeniem w branży izolacji przemysłowej. Zrealizowaliśmy projekty dla klientów z różnych sektorów przemysłowych, zdobywając ich zaufanie i uznanie.

Wszechstronność

Niezależnie od branży, w której działa Twoja firma, mamy rozwiązania izolacyjne dostosowane do Twoich unikalnych potrzeb.

Materiały najwyższej jakości

Dostarczamy tylko najlepsze materiały izolacyjne, aby zapewnić trwałe i skuteczne rozwiązania. Nasze materiały są nie tylko efektywne, ale także przyjazne dla środowiska.

Oszczędność kosztów

Nasze rozwiązania izolacyjne mogą znacząco obniżyć koszty operacyjne poprzez zmniejszenie strat cieplnych i energetycznych. To inwestycja, która szybko się zwraca.

Bezpieczeństwo

Dbamy o bezpieczeństwo naszych pracowników i klientów. Nasze prace są zawsze przeprowadzane zgodnie z najwyższymi standardami bezpieczeństwa. Stosujemy ekologiczne i bezpieczne materiały, które nie szkodzą środowisku.

Gwarancja wytrzymałości

Nasza firma oferuje również usługi konserwacji i utrzymania, aby zapewnić trwałość i skuteczność naszych systemów izolacyjnych przez lata.

Zgodność norm i przepisów

Jesteśmy doskonale zaznajomieni z obowiązującymi przepisami, normami i standardami dotyczącymi izolacji przemysłowej oraz posiadamy wymagane certyfikaty i pozwolenia.