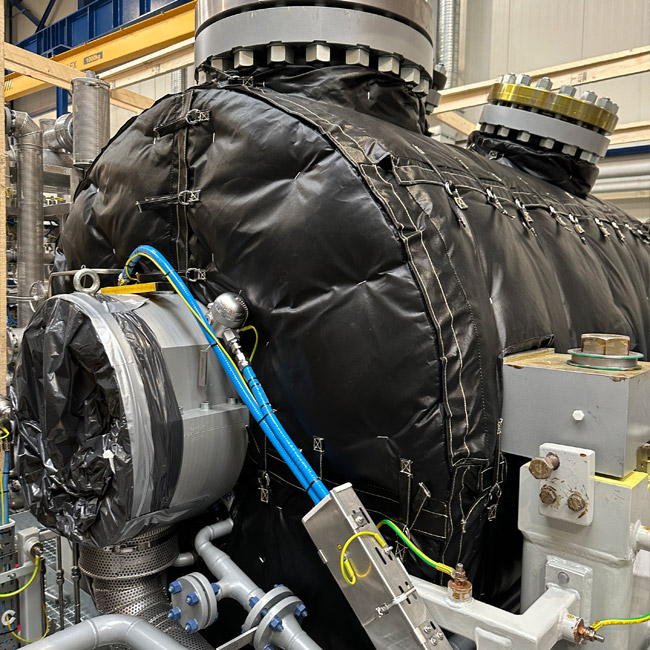

PetroStal offers high quality elastic thermal insulations in a textile protective coating – thermal insulating mattresses. They are used for the insulation of turbines, valves, flange connections, filters, exhausts, heat exchangers, containers and pipelines.

The production is individualized according to the dimensions and shape of the existing installation. They can be repeatedly assembled and disassembled, and any employee can assemble them without the necessity to undergo training and without using any tools. Mattresses can serve as an addition for insulation works where there is poor accessibility, in locations which cannot be insulated in a traditional way. They ensure perfect thermal and acoustic insulation.

The textiles are resistant to temperatures up to 1200°C (2192°F). These are high quality glass and silicate components coated with silicone, polyurethane, vermiculite, aluminium and PTFE. They can be used both outside and inside (they are resistant to weather conditions). They are resistant to chemicals, mould, vapour and fire.

They consist of the upper and lower textile layer, connected according to the thickness of insulation with an appropriate seam (heat-resistant threads).

According to the working conditions and the Customer’s requirements, mineral, ceramic or glass wool quilts are used as a filling. Mattresses are equipped with straps, glass ropes, Velcro fasteners, hooks, buckles and tapes which facilitate an easy and quick assembly or disassembly. In order to prevent movements of the insulation material inside, mattresses are quilted.

Additionally, mattresses can be equipped with a stainless steel net sewn in inside, as reinforcements against abrasion and mechanical damage.

Our mattresses are conform with PN-B-20105.