Waterproof Solution for Enhanced Insulation Protection

Identifying the optimal insulation system for specific applications presents considerable challenges. Beyond appropriate selection and application, the role of the insulation protection system is critical. Importantly, particular applications demand well-defined solutions: Certain processes necessitate fully waterproof and hermetic finishes, robust and easy-to-maintain, exhibiting long-term durability and chemical resistance.

Therefore, insulation protection should ensure superior safety, minimal maintenance costs, and reduced energy expenditures.

GRP consists of a fiberglass-reinforced polyester mat sandwiched between two layers of protective film. This composite material integrates resins, fiberglass, and specialized fillers. In its uncured state, GRP is flexible and malleable, allowing for custom shaping to fit various insulation profiles. Furthermore, it cures under UV light, at which point GRP becomes entirely waterproof, offering superior mechanical protection.

Durability

GRP forms seamless bonds that offer comprehensive waterproof protection to insulation, thus mitigating the detrimental impacts of adverse weather conditions (e.g., wind, rain, seawater) or general wear. The solution boasts chemical resistance and withstands substantial mechanical loads, supporting foot traffic.

Ease of Cleaning

GRP tolerates high-pressure cleaning methods without compromising the insulation integrity.

Cost-efficiency in Installation

On-site processing and installation mitigate pre-fabrication material costs.

Versatile Application

GRP efficiently insulates against thermal variances, applicable to underground and aerial cables and pipes, including marine environments. It conforms to diverse technical requirements.

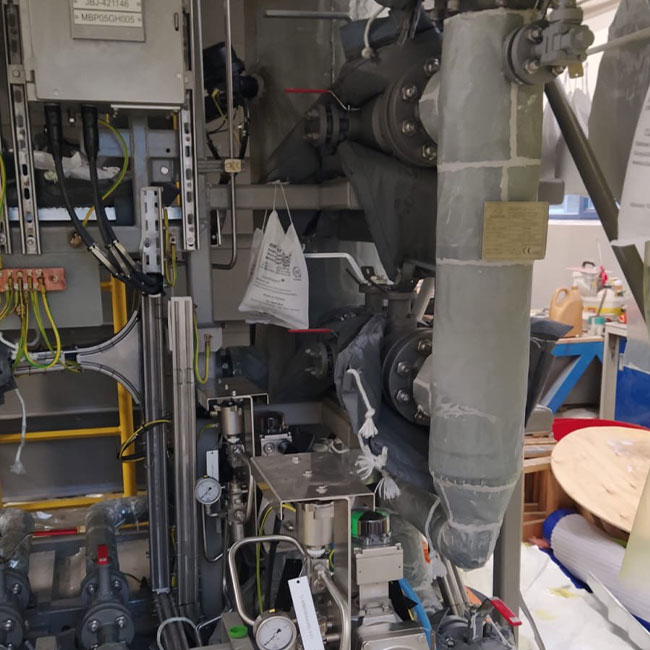

Food and Pharmaceutical Industries

Stringent insulation standards apply within the food and pharmaceutical sectors, focusing on preventing accumulation of contaminants, bacteria, or moisture within damaged insulation areas. Indeed, GRP offers an exemplary barrier ensuring impermeability and resistance around insulation for pipes, cables, tanks, and more, supporting industry hygiene standards.

Additionally, its resistance to high-pressure cleaning ensures that the insulation can be sanitized effectively without damage and the low vapor permeability of GRP, paired with insulation’s thermal resistance, forges a highly durable thermal insulation system.

Marine and Coastal Sectors

The harsh maritime conditions, including rain, wind, temperature fluctuations, and salt corrosion, typically damage pipe and cable insulation on ship decks, storage tanks, and drilling platform structures.

Obviously, GRP addresses these challenges efficiently through its waterproofing, high chemical resistance, mechanical strength, and seamless application, offering a reliable protection solution:

Moisture penetration and subsequent under-insulation corrosion are virtually eliminated.

On-site application of GRP simplifies the construction process, making obsolete the need for complex prefabricated insulation components.

GRP’s superior fire-resistant characteristics, compared to standard polyester finishes and non-flammable nature of the insulation, afford top-tier fire protection.

The material has been awarded the MED: Low Surface Flame Spread certification as per IMO A653 standards.

Tank Roof Insulation

Traditional tank roof insulation systems often succumb to damage from adverse weather and chemical exposure. Consequently, this damage increases maintenance costs and compromises safety, often outweighing the energy savings benefits of insulation.

However, applied directly on-site, GRP forms a seamless, robust coating over tank roof insulation, offering exceptional mechanical strength and durability, supporting foot traffic.

The recommendation for an anti-slip coating enhances safety, and specialized stringer constructions resist high wind loads, securing the insulation under extreme conditions.

The elimination of support structures for linings prevents under-insulation corrosion risks.

To conclude, GRP’s comprehensive coverage ensures long-lasting protection for both the insulation and the tank itself.

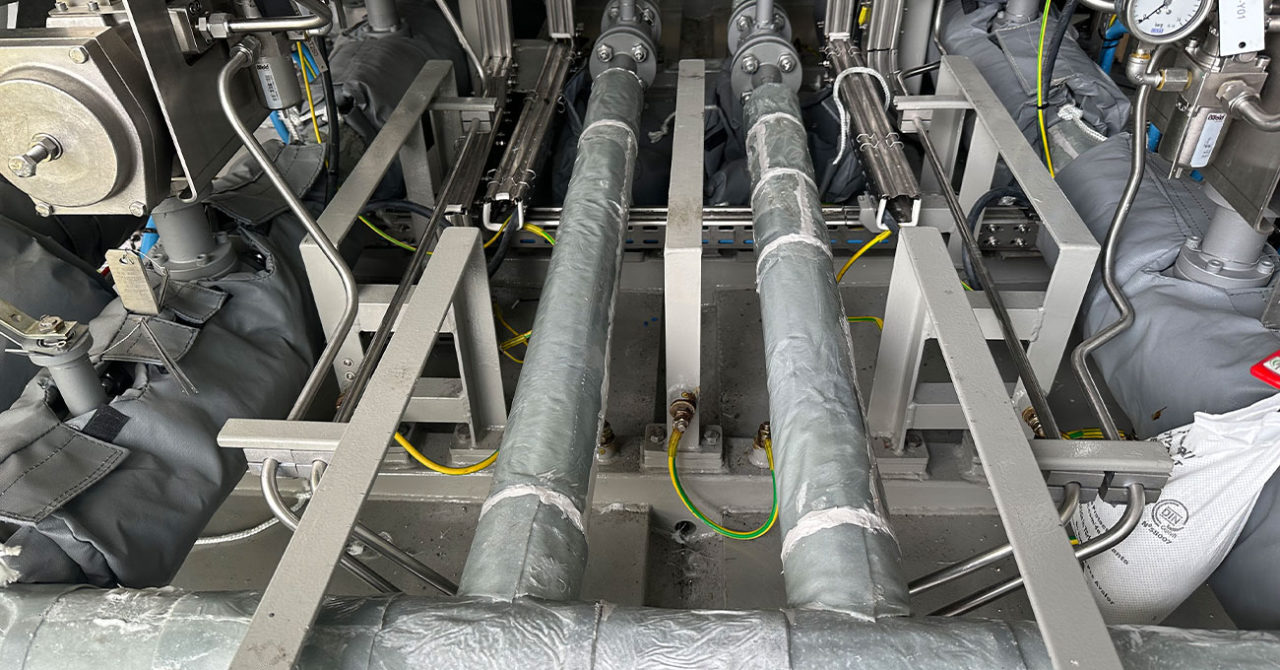

Chemical and Refinery Industries

Clearly, the significant carbon footprint of petrochemical facilities, exemplified by vast insulated piping and apparatus, necessitates robust insulation to maintain operational temperatures.

Subsequently, insulation damage from mechanical impacts, water ingress, or corrosive agents leads to significant efficiency losses and maintenance challenges.

GRP’s extensive testing and development cater to the stringent conditions of modern industrial environments, offering a reliable insulation protection solution.

Especially designed for petrochemical applications, GRP’s extensive compatibility extends to other sectors, offering optimal protection against aggressive chemicals for pipelines, tanks, reservoirs, and valves.

Benefits

Implementing GRP enhances insulation work quality, reduces operational costs, and promotes sustainable industrial practices.

Water Penetration Resistance: GRP’s seamless coverage ensures system waterproofing, diminishing under-insulation corrosion risks.

Its resilience against damage and vast chemical resistance extends insulation longevity, signifying GRP as a superior protective solution.